Welcome To Suzhou Guonuo Information Email: guonuo0172@gmail.com

The Intelligent Coal Flow Transport System effectively integrates AI video recognition with industrial control, focusing on the equipment of the coal flow system. It enables load identification and analysis of coal conveyor belts, and performs real-time transport capacity optimization and speed control. This intelligent regulation method assists coal mines in achieving reasonable regulation, balanced production, and coordinated economic operation by speeding up transport when there is more coal and slowing down when there is less. It enhances production efficiency, accurately identifies issues such as belt deviation, coal accumulation, foreign objects, water-coal mixture, and personnel intrusion, and intelligently responds to these situations, effectively reducing manual input and achieving the goal of reducing staff while increasing efficiency, making coal mine production more intelligent, efficient, and safe.

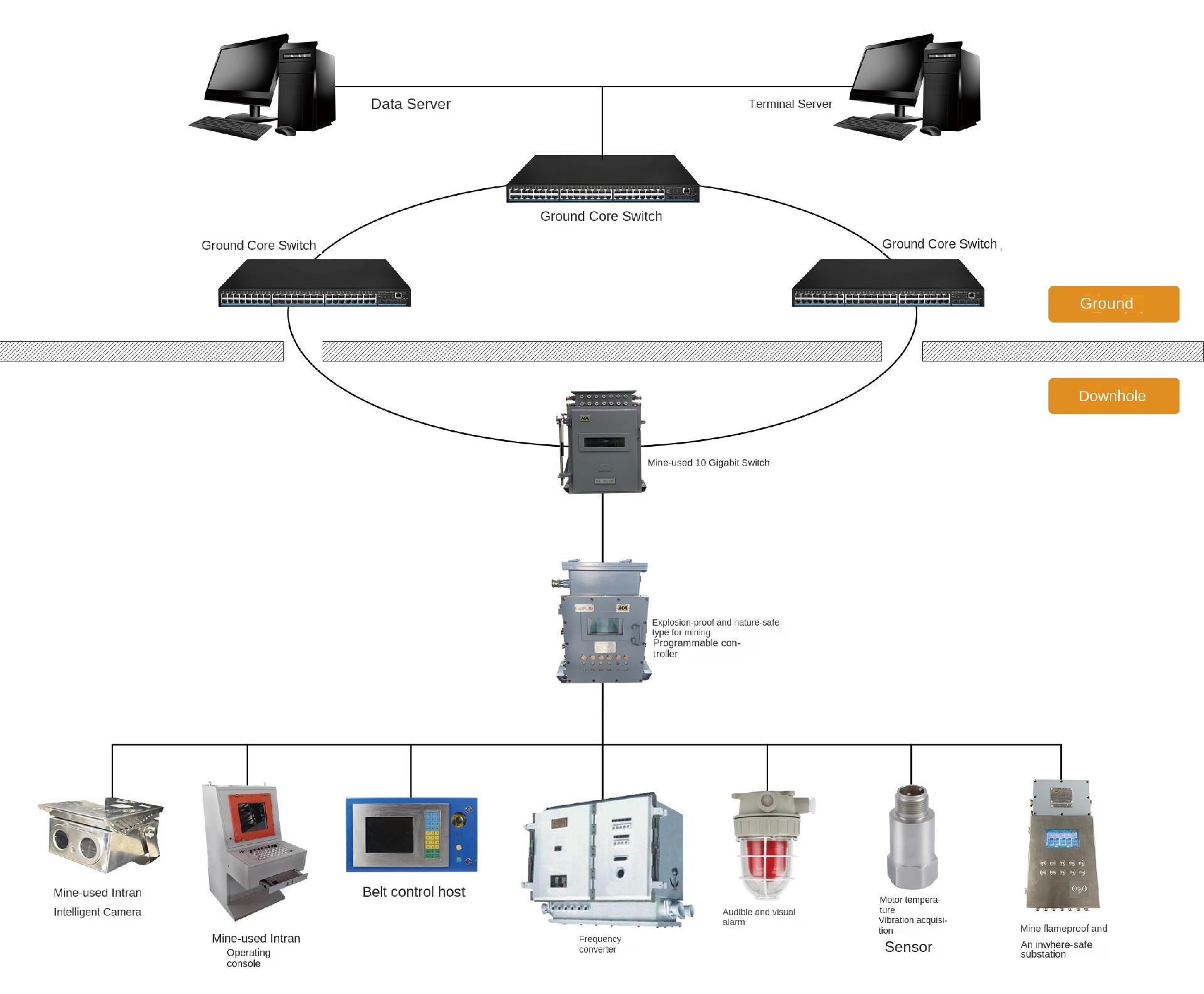

The system consists of mine-used explosion-proof and intrinsically safe programmable controllers, mine-used intrinsically safe AI smart cameras, mine-used intrinsically safe operation boxes, and a ground control platform.

1.Intelligent Speed Regulation

Based on coal volume information processed through PLC logic, instructions are sent to control the frequency output of belt conveyors and coal feeder inverters, enabling intelligent speed regulation of conveyors according to coal load and adjusting the coal feeding frequency of feeders based on belt load.

2.Intelligent Startup

It initiates startup in sequence along the coal flow based on coal volume information provided by detection devices, starting upstream equipment first and then downstream equipment as the coal flow approaches. Once downstream equipment is fully operational, corresponding interlocking relationships are established, with downstream equipment locking upstream equipment.

3.Intelligent Foreign Object Recognition

Using an AI smart camera system to capture images of high-speed moving belts for real-time analysis and upload to the ground control center for display and storage. It employs AI to achieve intelligent detection and early warning of belt coal accumulation, deviation, and personnel entering hazardous areas.

4.Reduced Labor Costs

The system can automatically monitor the coal flow status around the clock, replacing manual inspections, reducing labor intensity, and minimizing human errors and omissions.

5.Energy Saving

The system automatically adjusts the speed of the conveyor's inverter based on parameters such as coal volume and operating speed, achieving energy-saving control by running faster with more coal, slower with less coal, and standby with no coal, thereby reducing energy consumption.

6.Reduced Transport Costs

The system intelligently plans vehicle routes based on the actual situation of the coal mine, avoiding repeated vehicle travel and congestion, thus lowering transport costs.