ICS-17A electronic belt scale

The ICS-17A electronic belt scale is a four roller, double bar mining explosion-proof electronic belt scale, which uses two pull sensors and a frictionless ear axle support on the outer side. It can effectively overcome the influence of bias load and slope on accuracy, and has stronger environmental adaptability.

Performance Characteristics

Higher precision

Four rollers, double bar structure, two pull sensors, double bar pivot point, small horizontal force, relatively high measurement accuracy.

Stable operation

The weighing area is long, with strong filtering ability and greater stability. Explosion proof intrinsic safety type, maintaining stability in explosive hazardous environments.

Strong adaptability

Unique rectangular lever, with good rigidity and invisible deformation. Non friction rubber ear shaft support, corrosion-resistant, moisture-proof, and vibration resistant.

Easy installation

The double roller and double bar belt scale has a simple structure, easy installation and debugging, small maintenance amount, and low maintenance cost.

Product Composition

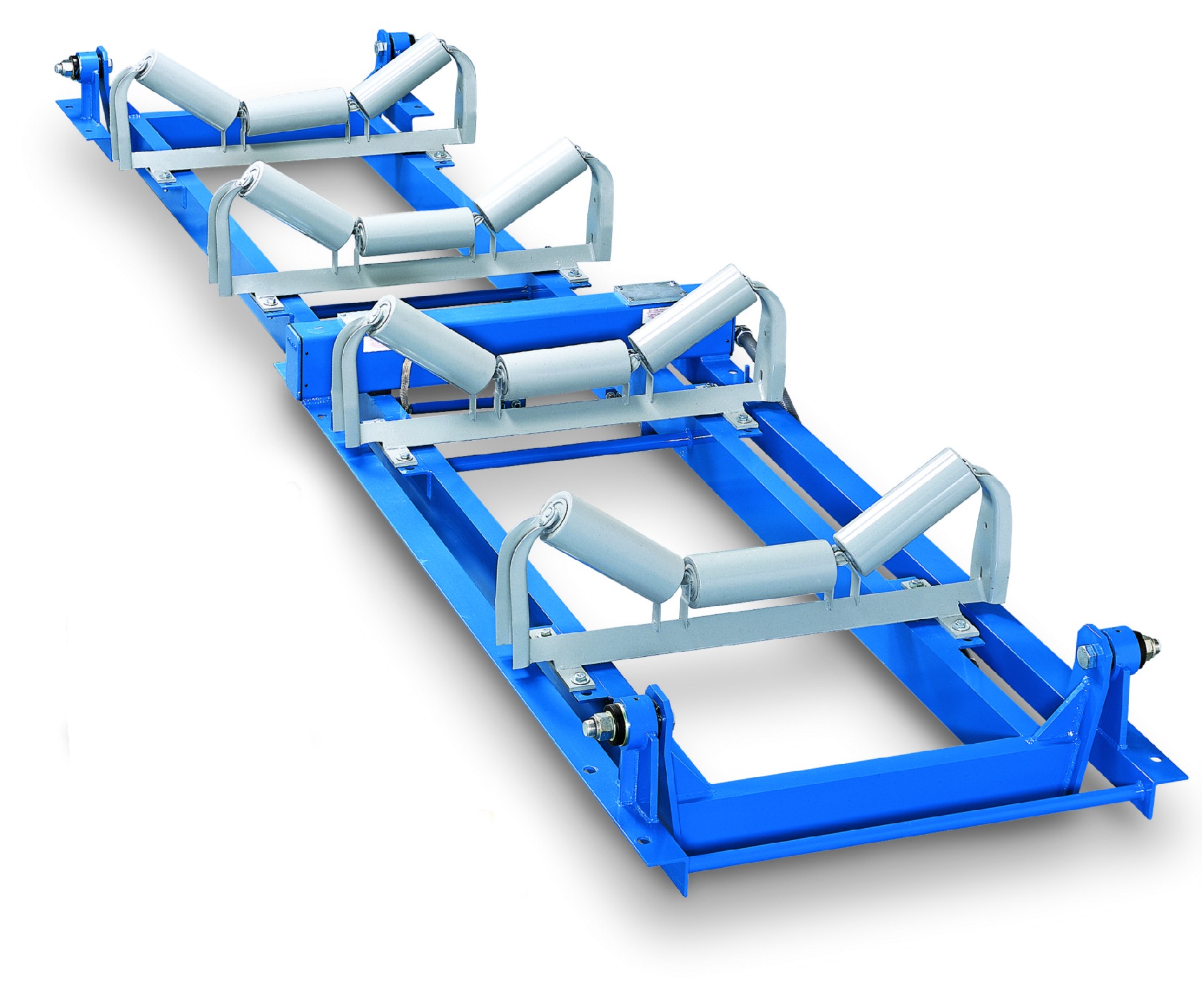

ICS-17A Weighing bridge

The four roller double bar structure design adopts two pull type sensors, and the outer support adopts a frictionless ear pivot point, which can effectively overcome the influence of bias load and slope on accuracy, and has stronger environmental adaptability.

Touch screen weighing instrument

The belt scale instrument adopts 32-bit 180MHz high-speed operation processing to ensure stable operation and calculation accuracy, and a 16 bit DA converter ensures more accurate 4-20mA output. This machine has a large capacity storage space, and its storage capacity can be queried for daily/monthly historical data storage and query functions. The data storage adopts FLASH mode, which can automatically save various process data when the system is powered off. After powering on again, the system will continue to run on the data.

Digital weighing sensor

The independently developed industrial grade digital second-generation weighing sensor enhances the dynamic digital filtering function and adds linear compensation function on the basis of the original generation digital sensor. It overcomes the disadvantages of traditional sensors such as small output signal, short transmission distance, and poor anti-interference ability, making the data during dynamic weighing more authentic, stable, and reliable.

Speed encoder

The double-sided rubber coating effectively prevents the belt from slipping, and the carbon steel shell has good mechanical strength, shielding and sealing properties suitable for outdoor installation. The brushless DC pulse generator does not require adjustment, calibration or maintenance, and the coaxial connection structure more effectively ensures speed measurement accuracy and greatly improves the service life of the equipment.

Product Parameter

| Model | Calibration Accuracy | Operating Accuracy | Conveyor Incline Angle | Weight Sensor | Speed Sensor | Weigh Bridge Frame | Weighing Roller |

| ICS-14A | ≤±0.125% | ±0.5% | ≤6° | 4 | 1 | Suspended Type | 4 |

| ICS-17A | ≤±0.25% | ±0.5% | ≤17° | 2 | 1 | Double Lever Type | 4 |

| FSD-M1 | ≤±0.25% | ±0.3% | ≤17° | 4 | 1 | Fully Suspended Type | 2 |

| FSD-M2 | ≤±0.2% | ±0.25% | ≤17° | 8 | 1 | Fully Suspended Type | 4 |

| FSD-M4 | ≤±0.125% | ±0.2% | ≤17° | 16 | 1 | Fully Suspended Type | 8 |

Working Principle

-

Generate signal

The weighing bridge is installed on the conveyor frame. When the material passes by, the measuring roller detects the weight of the material on the belt conveyor and acts on the weighing sensor through a lever, generating a voltage signal proportional to the belt load.

-

Speed calculation

The speed sensor is directly connected to the large-diameter speed measuring drum, providing a series of pulses, each pulse representing a belt movement unit, and the frequency of the pulses is proportional to the belt speed.

-

Calculation results

The weighing instrument receives signals from the weighing sensor and speed sensor, integrates them to obtain an instantaneous flow rate value and a cumulative weight value, and displays them separately.