Synchronized Hardware and Software Upgrades for Enhanced Scalability and Intelligence of Electronic Belt Scales

With advancements in information technology and the Internet of Things (IoT), electronic information systems have become increasingly powerful and miniaturized. In a comprehensive functional system, hardware and software are no longer distinct entities but complement each other, working synergistically to create a holistic solution.

The modular and intelligent systems centered around software are continually improving, with software enhancing the functionality and stability of hardware. This trend is evident in the weighing instrument industry as well. Software is finding wider applications in weighing instruments. For instance, during design, multi-point calibration within the measurement range is achieved through software, reducing all errors (except for variable errors) to zero for ideal accuracy. Additionally, signal auto-recognition technology is incorporated to distinguish between variable signals and gross interference signals.

Electronic belt scales leverage software technology to eliminate inherent hardware delay effects, enhancing dynamic measurement performance. Software's calibration and correction capabilities reduce hardware costs while improving accuracy and long-term stability.

In the field of measurement, electronic belt scale manufacturers are increasingly aware of software's role in enhancing overall performance, stability, scalability, and intelligence. From the outset of design, they emphasize a hardware-software co-design approach, using unified methods and tools to describe, integrate, and validate both software and hardware. This approach avoids the drawbacks of independent design and prioritizes software solutions during initial design stages.

Guonuo Technology's new FSD high-precision electronic belt scale exemplifies hardware-software synergy. In terms of technical compensation, to address temperature-related measurement errors, the instrument is equipped with a built-in temperature sensor that monitors real-time environmental temperature changes and incorporates them into the algorithm. It also compensates and corrects for changes in sensor zero points and sensitivity coefficients, achieving intelligent temperature compensation.

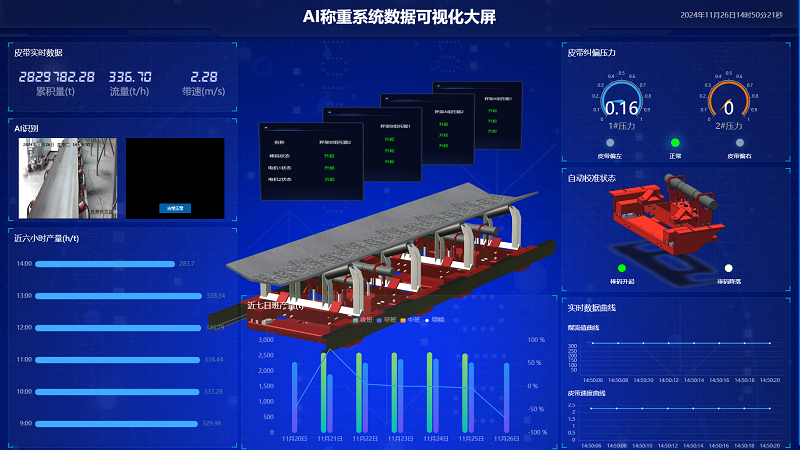

By utilizing information technology, electronic belt scales can be integrated into corporate LANs, enabling communication with other computers and breaking down information silos. Metering information can be transmitted to other devices in real-time and effectively. Software systems can process, store this data, and generate visual reports, enhancing scientific enterprise management.

Furthermore, in terms of software applications for weighing instruments, Guonuo Technology has developed an intelligent weighing management cloud platform. Leveraging IoT, cloud computing, and information technology, this software system offers data acquisition, processing, fault diagnosis, and other functions. It provides unified intelligent management for weighing instruments, including electronic belt scales, contributing to the overall intelligent and scientific management of enterprise equipment.

Electronic belt scales, as weighing instruments, have long overlooked the application of software technology. However, with the growing recognition and application of software in weighing technology, the development and application of application software and configuration software are continually strengthened. By applying more software functional modules and synchronously upgrading hardware and software technologies, significant enhancements in scalability and intelligence of weighing instruments can be achieved.

Belt Type Quantitative Feeder: Making Feed Feeding More Continuous, Efficient, Precise, Reliable

Belt Type Quantitative Feeder: Making Feed Feeding More Continuous, Efficient, Precise, Reliable

High-Precision Belt Scales in Coal-Fired Power Plants: Facilitating the Realization of Digital Management in Coal Yards

High-Precision Belt Scales in Coal-Fired Power Plants: Facilitating the Realization of Digital Management in Coal Yards

Coal Industry: Leveraging Digital Weighing and Metering Systems for Unmanned Smart Metering

Coal Industry: Leveraging Digital Weighing and Metering Systems for Unmanned Smart Metering

Improving Loading Measurement Accuracy and Efficiency: It All Depends on Loader Electronic Scales

Improving Loading Measurement Accuracy and Efficiency: It All Depends on Loader Electronic Scales

Belt Automatic Weighing and Batching Control System: Precise Measurement and Control for More "Satisfactory" Applications

Belt Automatic Weighing and Batching Control System: Precise Measurement and Control for More "Satisfactory" Applications

Matrix-type High-Precision Belt Scale + Measurement Cloud Platform: Empowering Smart Factory Construction

Matrix-type High-Precision Belt Scale + Measurement Cloud Platform: Empowering Smart Factory Construction

Digital High-Precision Matrix Belt Scale: Driving a New Engine for the Development of Industrial Bulk Material Metering

Digital High-Precision Matrix Belt Scale: Driving a New Engine for the Development of Industrial Bulk Material Metering

Coal Production Remote Monitoring System: Improving Coal Production Supervision Mechanisms to Avoid Over-Capacity Production

Coal Production Remote Monitoring System: Improving Coal Production Supervision Mechanisms to Avoid Over-Capacity Production

Systematic Application of Automatic Weighing and Batching Machines in Industrial Automation

Systematic Application of Automatic Weighing and Batching Machines in Industrial Automation